Transforming Oatly’s UK supply chain to deliver their sustainability objectives

Ongoing creation of Oatly’s First UK facility within a total capex of £200m and utilising best in class automation and sustainability solutions. Upon completion, the factory will be one of the world’s largest plant-based dairy establishments, with the capacity to produce 450 million litres of oat drink per year!

Project overview

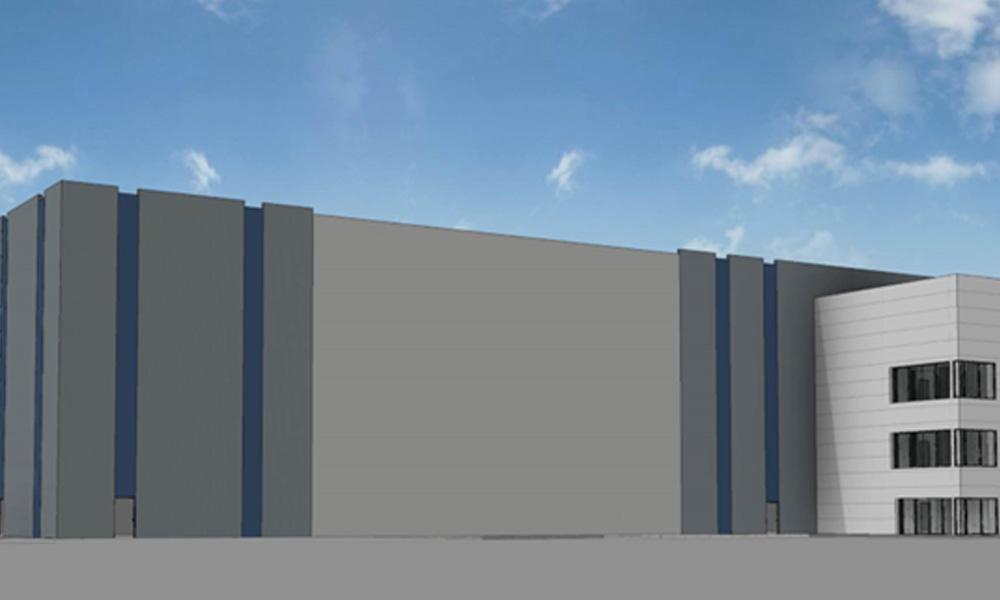

Conversion & fit out of a 34000 m² existing warehouse with capacity to produce up to 450 million litres of oat milk products per year.

Challenge

The project involves complex mechanical and process design integration. One of the key build challenges is to accommodate this in a fast-paced changing environment.

“We have worked with NIRAS from the initial footprint analysis and their proven evaluation model has enabled us to make clear investment decisions. We are delighted to be partnering with them on this transformational project.”

– Operations Director at Oatly

Duration: 16 months

Construction Project value: £90m

Total project value: £200m

“We have worked with NIRAS from the initial footprint analysis and their proven evaluation model has enabled us to make clear investment decisions. We are delighted to be partnering with them on this transformational project.”

– Operations Director at Oatly

Related case studies

Complete refurbishment and remodel for Haydens